Our Open Hardware Designs

Open Hardware

The Zcapture team are strong believers in open source technologies. To this end we have endeavored to design and build a product that not only uses open source products available on the market but we also believe in sharing our design with the public at large free of will. While we realize that not everyone wants to hand build their own version of the Zcapture system we believe that by sharing these designs it empowers people to create solutions that keep an emerging industry in check by lowering the cost of ownership of solutions and creating competition and diversity. Below you will find the design files for the "Zcapture One", our first Zcapture model design that has been in use in our studios for over a year. We will have a limited number of kits available in our store as well.

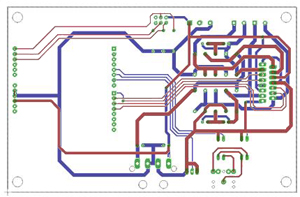

Board Layout

The board layout for the Zcapture is designed with a dual layer copper clad board. The Unit Dimensions are: 4.300 x 3.600 and the Material Type is: FR4, With a Material Thickness of: 0.062". The board has been designed with some ability to break out or expand its functionality with additional IO already layered out and other accessory terminals and jacks if needed. But the base functionality of the board is spot on for an appropriately sized motor. Download Here

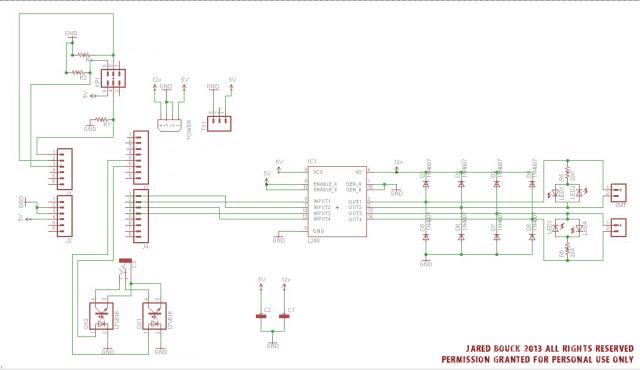

Circuit Design

The circuit design for the Zcapture system has been through several revisions and has been developed to support an arduino, acting more as a motherboard. The board is designed with all appropriate IO breakout as well as an onboard motor driver circuit and optically isolated jacks for camera connectivity. This simple but robust design is ideal for driving most Nema 17 stepper motors with the addition of a 5V active cooling system. Download HereChassis Design

The chassis for the Zcapture system is designed to be compact and easy to assemble and maintain. Made from .118 acrylic it is strong and light weight. With layout for all the ports needed for the Zcapture board and mounts for the motor and system cooling fan it is well built while not using too much precious material to keep costs in check. The design file is intended to be used with a laser cutting service and has tolerances set accordingly for the tongue and slot setup. Download Here

Build guides and part lists are coming soon so stay tuned!